Industrial innovation accelerator

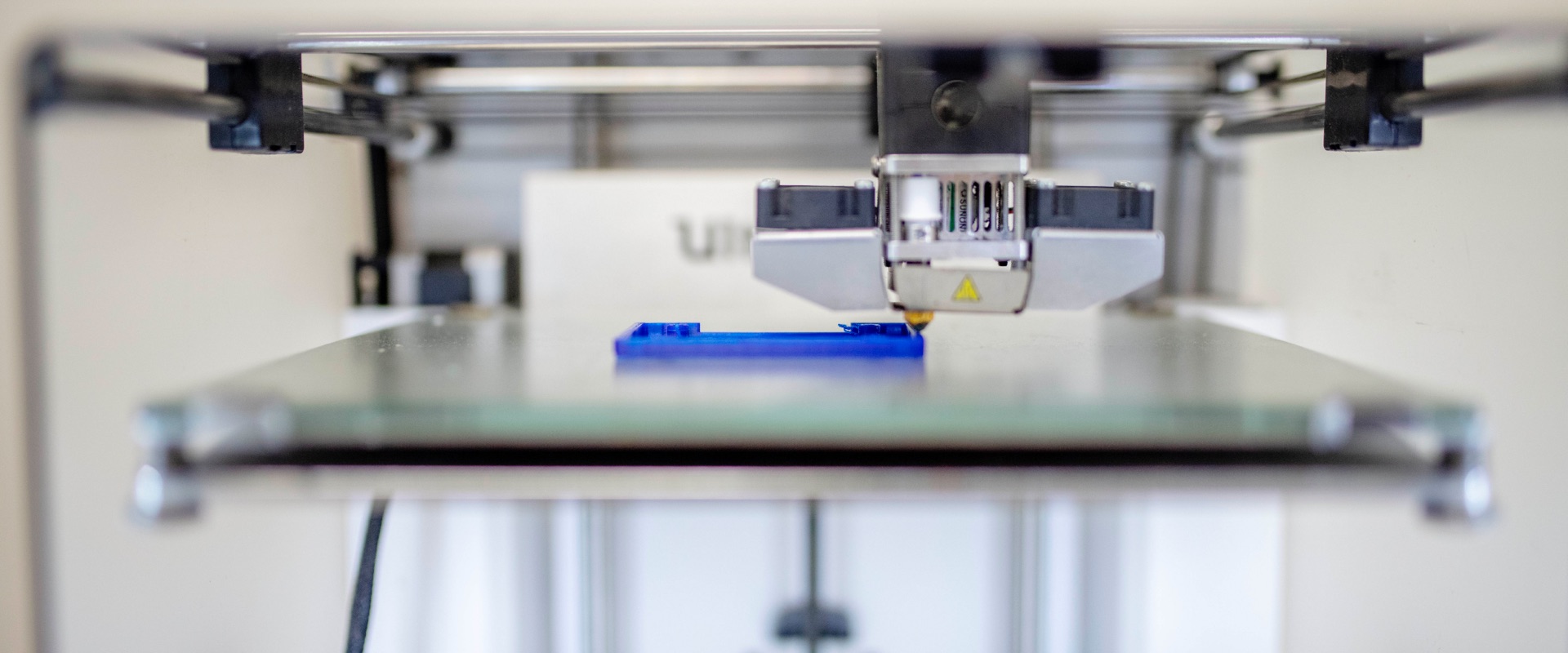

Additive manufacturing is proving to be a driver of good ideas in industrial design. Integrating it into the creation process enables:

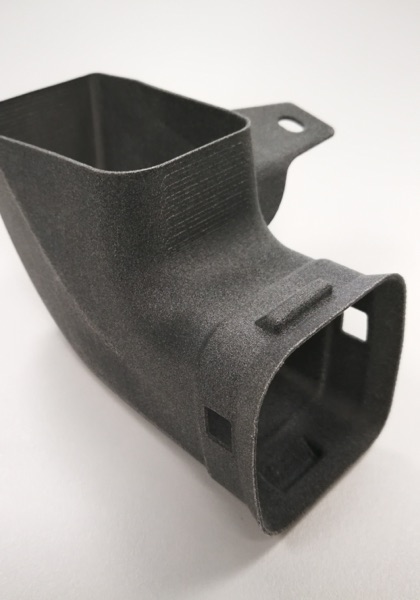

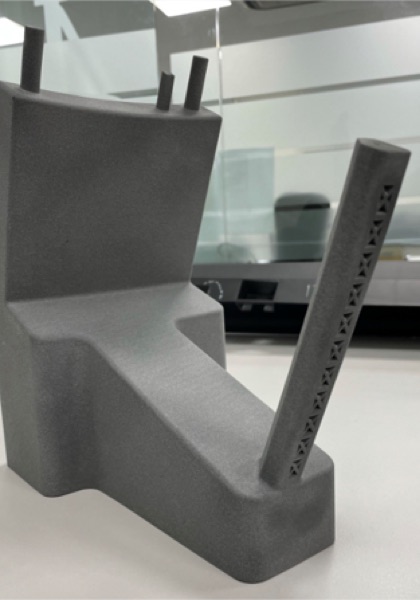

- The development, evaluation and improvement of prototypes in record time

- Overcoming former physical limits - as we are now able to manufacture structures that were not feasible with injection moulding

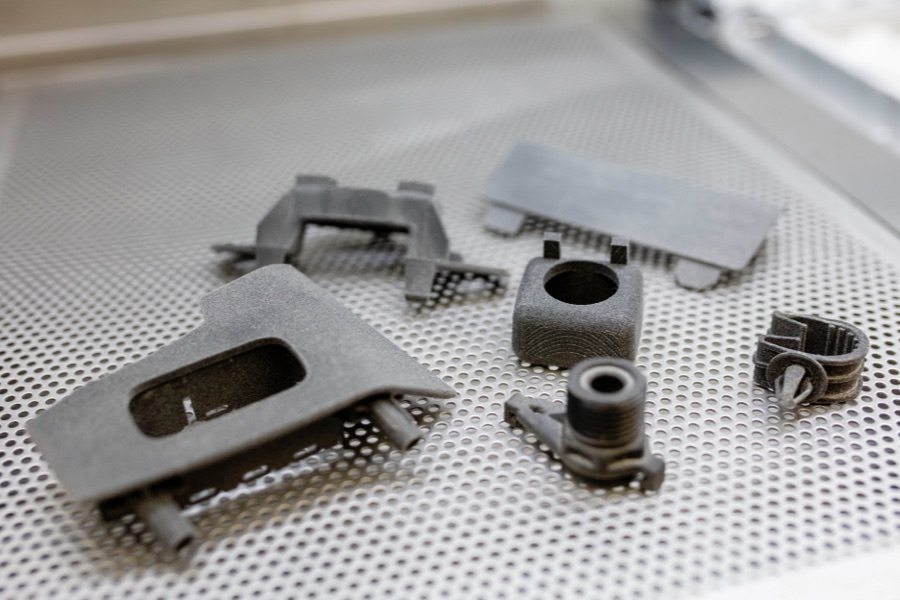

- Being able to devise new parts that are lighter and able to integrate several elements that previously overlapped or were assembled

- Eliminating assembly steps and simplifying supply chains